- +86 135 2431 2142

- eric@recolortech.com

- Mon - Fri: 9:00 - 20:30

MIMAKI TRAPIS (Transfer Pigment System)

Printer + Dedicated ink + Dedicated transfer paper + Dedicated transfer machine

Contact us for shipping, installation, tariffs and warranty..

- 2 Pcs Print Heads

- Max. Printing Size 1610 mm (63.4 in)

- Sb411

Printing Speed

TS330-1600 Printer 4 Color printing

| Model | Resolution | Pass | Printing Speed (m2/h) |

|---|---|---|---|

| Super Draft | 300×600dpi | 1 | 135 |

| Draft | 600×600dpi | 2 | 69 |

| High Speed | 600×600dpi | 4 | 45 |

| Standard | 600×1200dpi | 6 | 30 |

| High Quality | 600×1200dpi | 8 | 21 |

TS330-1600 Printer 6/7/8 Color printing

| Model | Resolution | Pass | Printing Speed (m2/h) |

|---|---|---|---|

| Draft | 600×600dpi | 4 | 45 |

| High Speed | 600×600dpi | 6 | 30 |

| Standard | 600×900dpi | 8 | 21 |

| High Quality | 600×1200dpi | 12 | 13.2 |

MIMAKI Technology

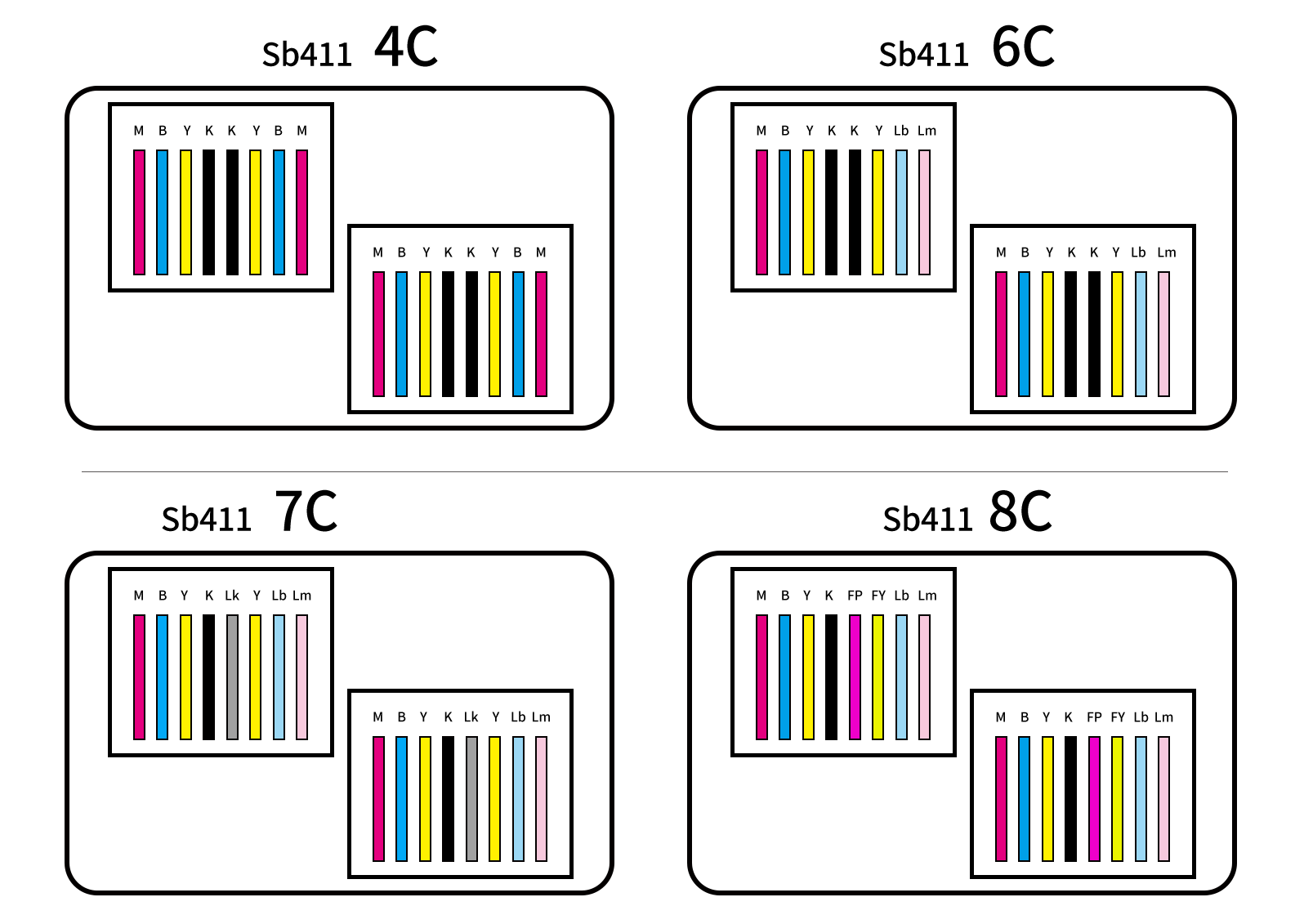

Ink Color Configuration

Benefits & Features

“Textile printing made simple” The next generation textile printing system that is friendly to the environment and humans

“TRAPIS” is our pigment transfer textile printing system, named after the words “Transfer,” “Pigment,” and “System.”

The system consists of our inkjet printer, specialized ink, specialized transfer paper, and a specialized transfer press from a recommended European manufacturer.

Product outlines

This simple textile printing system, which requires only printing and transfer, is easy for anyone to operate, requiring no specialized skills or knowledge, unlike traditional textile printing systems.

It requires minimal installation space, allowing textile printing operations to be carried out at the forefront of fabric supply and distribution, such as in stores and design offices.

This process produces virtually no wastewater. Even including wastewater from transfer paper production, wastewater discharge is reduced by approximately 90% compared to traditional digital dyeing systems.

A single type of ink can be used to print on a wide variety of textile fabrics.

Printing on transfer paper eliminates the complex maintenance of fabric conveyor belts required by traditional digital textile printing.Color is as excellent as traditional textile dyeing, and printed fabrics exhibit standard lightfastness.

The ink is ZDHC MRSL Level 3 certified. This system ensures worker and consumer safety and is environmentally friendly.

Core Technologies:

- Waveform Control

- Mimaki Advanced Pass System

- Nozzle Check Unit

- Nozzle Recovery System

- Mimaki Fine Diffusion

Printing Materials:

- Tapestry

- Flag

- Sports

- Apparel

- Interior Fabrics

- Fashion Textile

- Linen / Nylon

- Hemp / Spandex

- Canvas / Polyester

- Cotton-Polyester / Cupro

Specifications

| Item | TS330-1600 |

|---|---|

| Print head | 2 Pcs Print Heads |

| Printing resolution | 300 dpi, 600 dpi, 900 dpi, 1200 dpi |

| Ink Type/color | Sb411, 2L ink pack / Sb410 (Fy, Fp) |

| Interface | Ethernet 1000 BASE-T / (USB2.0 High-speed) |

| Power supply | Single phase AC100-120/200-240V±10% 50/60Hz±1Hz |

| Power consumption | 1,400W or less |

| Operation environment | 20°C to 30°C (68°F to 86°F)/35 to 65% RH (No condensation) |

| RIP Software | TxLink4 Standard /RasterLink7 |

| External dimensions (W × D × H) | 3,170×820 × 1,305 mm/ 124.8 × 32.3× 51.4 in |

| Weight | 240 kg / 529.1 lb |