- +86 135 2431 2142

- eric@recolortech.com

- Mon - Fri: 9:00 - 20:30

CF2 Series Flatbed Cutting Plotter

Compact multifunction flatbed cutting plotter

Contact us for shipping, installation, tariffs and warranty..

- Composite materials etc. can be half-cut

- Half-cut and Die-cut

- Mark-sensor function

FUNCTION

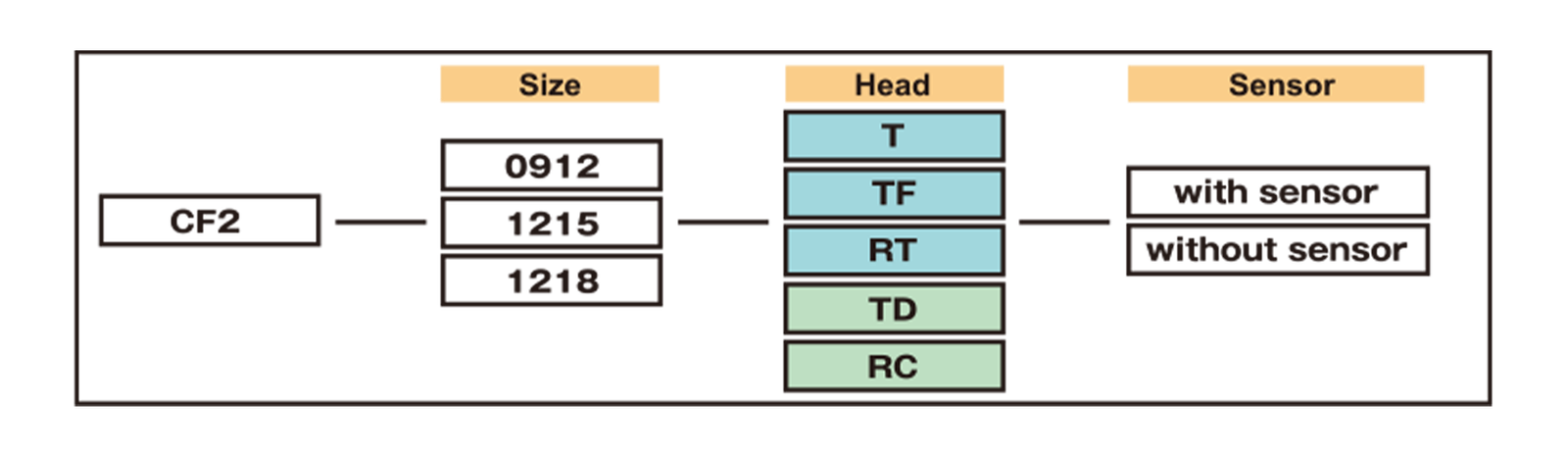

LINE-UP

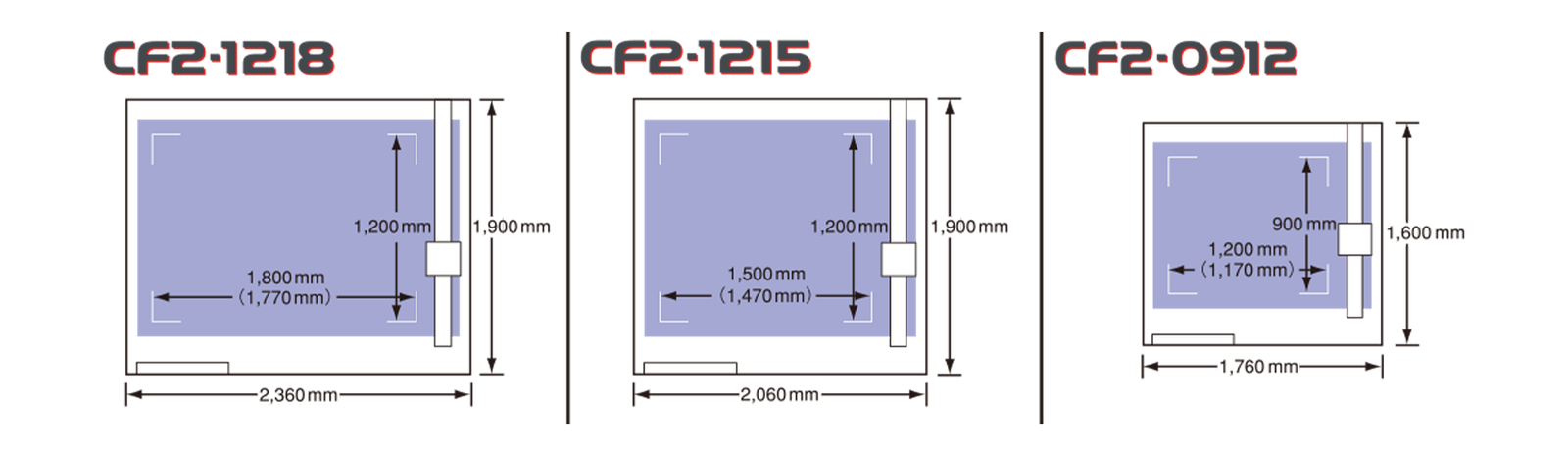

CUTTING SIZE

Benefits & Features

Use CF2 to achieve multi-type small batch production.

The CF2 Series flatbed cutting plotters deliver high-precision cutting of a wide range of media without the need for molds. With 30 models to choose from, you can select the most suitable model for your needs. By cutting printed media, you can produce high-value-added products on demand. Enable high-variety, low-volume production with unprecedented quality.

Composite materials can be half-cut.

By adjusting the depth of the blade, you can half-cut composite materials, laminated materials, etc. Since two knives can be used, different types of half-cuts or die-cuts can be made without changing the knives.

Marker sensor function

A high-performance color photoelectric sensor detects the square registration marks printed on the media and adjusts the origin position, coordinate tilt, and distance.

This allows the operator to precisely cut at the desired location. Furthermore, the sensor can distinguish between the color of the media and the color of the square registration marks, enabling the cutter to accurately cut regardless of media color and adjust to the printed material. A standard indicator light serves as a guide when setting up the media, making it easier for the operator to adjust the position based on the square registration marks.

Media is set easily and accurately

The installation of guides in the X and Y directions allows for smooth media positioning, improving work efficiency. Furthermore, the guides can be removed to suit the media size.

Wide variety of blades

We offer a wide variety of blades suitable for various media. Flexible processing with a single machine expands your business opportunities.

Common blades available on the market can also be used.

Application:

- Sign & Display

- POP

- POS Display

- Package

- Industrial Cut

Printing Materials:

- Seam panels

- Foam materials

- Plastic tape

- FPC boards

- Full-size panels

- Laminated POP

- Signage

- Coated boards

- Toys

- Decorative boxes

- Double-sided corrugated cardboard

Specifications

| Item | CF2-0912 | CF2-1215 | CF2-1218 | ||

|---|---|---|---|---|---|

| Effective plotting area | X | Sensor model | 1,170 mm (46.1 ") | 1,470 mm (57.9") | 1,770 mm (69.7 ") |

| No sensor model | 1,200 mm (47.2") | 1,500 mm(59.1") | 1,800 mm (70.9") | ||

| Y | 900 mm(35.4") | ||||

| Motorization | X,Y,Z,θ 4 axes DC software servo | ||||

| Maximum plotting speed | 50 cm(19.7")/s | ||||

| Maximum acceleration | 0.5 G | ||||

| Mechanical resolution | X:0.00234 mm(0.00009") Y:0.003125 mm(0.0001") θ:0.05625 | ||||

| Command resolution | 0.025 mm(0.001")/0.01 mm (0.0004") (changeable from operation panel) | ||||

| Static accuracy | Repetition accuracy | ±0.1 mm(0.004") | |||

| Distance accuracy | ±0.1 mm(0.004")or +0.1 % whichever is greater | ||||

| Origin repetition accuracy | ±0.1 mm(0.004") | ||||

| Maximum thickness of set work | T/TD :25 mm(1")RT/ RC : 20 mm (0.8 ") | ||||

| Work fixation | Air suction by a blower | ||||

| Receiver buffer size | 1MB | ||||

| Command | MGL-Ⅱ c3 (Support MGL- Ⅱ c) | ||||

| Interface | RS-232C | ||||

| Dimension | Width | 1,760 mm (69.3 Ⅱ") or less | 2060 mm (81.1")or less | 2360 mm(92.9") or less | |

| Depth | 1,600 mm (63.0") or less | 1900 mm (74.8 ") or less | |||

| Height | 1,100 mm (43.3 ")or less | ||||

| Weight | 140 kg (308 lbs.) | 165 kg (364 lbs.) | 180 kg (397 lbs.) | ||

| Operation environment | Temperature:5-40°C Humidity:35-75%(Rh)No condensation | ||||

| Power requirement | Main Unit :50/60 Hz AC 100/120/220/240 V(tap changing) Blower : Stated separately | ||||

| Power consumption | Main Unit : 300 VA Blower : Stated separately | ||||